Wires. Lines. Cables. EXTRUMATIC®.

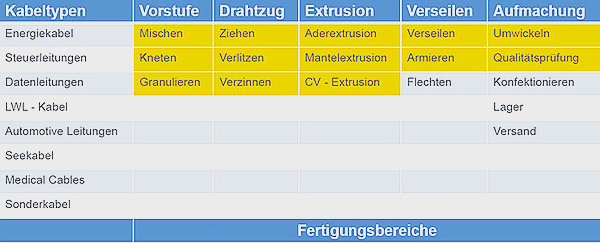

Only a few other industrial sectors are as strongly shaped by their similar type spectrum as the wire and cable industry is.

The categories of power cables, communication lines, control lines and special lines allow only a rough classification.

The real diversity comes from various parameters like voltage range, installation type, environmental conditions, insulating materials, screening, temperature range, etc.

The real diversity comes from various parameters like voltage range, installation type, environmental conditions, insulating materials, screening, temperature range, etc.

The wide range of cable types requires the same kind of diversity in manufacturing processes and machines for wire and cable production.

The Kühne + Vogel range of services for the wire and cable industry

At an early stage, Kühne + Vogel GmbH identified the wire and cable industry’s need for a largely standardized, modular automation system that would cover the various manufacturing levels while also handling the entire vertical integration, from the sensor/actor level to the company management level.

Based on thorough needs analyses and requirement profiles, Kühne+Vogel GmbH developed the first high-performance EXTRUMATIC® process controls more than twenty years ago, at the time based on SIMATIC S5 155U.

Downloads:

MSR Magazin 1993/11-12

MSR Magazin 1994/10

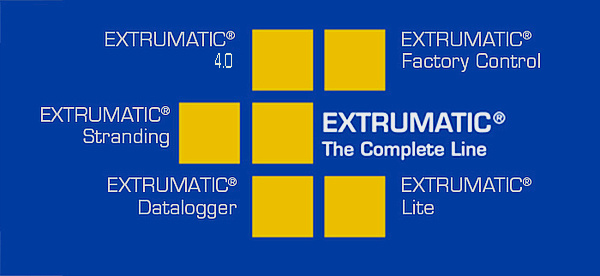

Since then, EXTRUMATIC® has proven its value hundreds of times over in the daily work of many well-known cable manufacturers. The constant, consistent further development of its performance and scope of service by Kühne+Vogel GmbH’s engineers and software developers led to the versions in use today, the EXTRUMATIC®IT and EXTRUMATIC®FactoryControl.

The advantages of EXTRUMATIC®4.0

In a growing but highly competitive market where it is essential to put new cable types on the market as quickly as possible while also responding flexibly to customer requirements, cable manufacturers can secure decisive competitive advantages by using EXTRUMATIC®IT. The following arguments speak for themselves:

EXTRUMATIC®IT guarantees users the following:

- More process transparency

- More manufacturing flexibility

- Consistently high manufacturing quality

- Minimizing waste

- Reducing startup length

- Optimizing all of the resources used

EXTRUMATIC®IT is the consistent automation platform for every step of cable production. The client/server architecture guarantees efficient order and quality management for users. All of the important functions are included in the basic scope of delivery and can be used right away:

- Automatic Process Control

- Production Order Management

- Recipe Management

- Quality Management

- Machine Information Management

- User Identity Management

- Long-Term Archiv *)

*) Long-term archiving up to 15 years, as an additional module

This is what EXTRUMATIC®FactoryControl is all about

With EXTRUMATIC®FactoryControl, cable manufacturers can effortlessly network all of their EXTRUMATIC®IT manufacturing systems. Since 2010, EXTRUMATIC®FactoryControl has been part of the basic scope of delivery for every EXTRUMATIC®IT system. At no additional charge.

That makes EXTRUMATIC®IT/ FactoryControl’s price-performance ratio unbeatable.

Further innovations from the EXTRUMATIC® product family

Because of our customers’ constant requests for complete, turnkey manufacturing plants, the EXTRUMATIC® product family was expanded to include the EXTRUMATIC®Turnkey module.

Another important addition to our product family is the EXTRUMATIC®Stranding machine program.